Busbar punching, cutting and bending machine: 3 in 1, economical and efficient

SUNSHINE™ busbar machine have an annual sales volume of over 1,100 units due to their multi-functional and cost-effectiveness, and are highly favored in the electrical panel or high and low voltage switchgear manufacturing industries. Whether you require busbar punching, cutting, and bending, or require more complex busbar processing, SUNSHINE offers proven technical solutions to meet your aluminum and copper busbar processing needs.

SS-50-3CNC Busbar Punching Machine

$ Request Price

SS-80-3CNC Busbar Cutting Machine

$ Request Price

SS-30-3CNC Copper Busbar Machine

$ Request Price

SUNSHINE™ standard 3-in-1 busbar machine features a three-station design consisting of a punching unit, a bending unit, and a cutting unit, integrating busbar punching, cutting, and bending functions into a single machine. Equipped with three high-power motors, it delivers a max hydraulic output of 800KN. Three people can operate the machine simultaneously without interrupting other workstations, significantly improving busbar processing efficiency. With a low initial investment cost, it is ideal for small-scale electrical panel manufacturers and switchgear factories with limited budgets.

- Three independent motors allow simultaneous operation of all stations.

- Processed sections are smooth and burr-free.

- Affordable and highly productive.

- Simple operation and easy to learn.

Contact us to learn more about our busbar processing machine or to request best quote.

SUNSHINE™ standard 3-in-1 busbar machine only supports PLC in the bending unit, while the punching and cutting units lack PLC configuration. This is a key difference from professional 3-in-1 busbar machine. The bending unit’s PLC has built-in standard bending modes: six bending modles. Simply input the bending angle to easily achieve any busbar bending angle. The punching unit and cutting unit can only be manually calibrated through the ruler to calibrate the coordinates of the busbar processing position to achieve the punching and cutting processing effects.

If you have a sufficient budget and demand high production efficiency, please check out our PRO series: Professional 3-in-1 busbar machine. This series differs from the standard 3-in-1 busbar machine in that the punching, cutting, and bending units are all PLC-enabled, and the servo system is also added, with three PLC touch screens and four servo systems.

Whether you’re bending, punching, or cutting busbars, the operator simply enters the parameters, and Professional 3 in 1Busbar Machine automatically and quickly locates the busbar processing coordinates, eliminating the need for manual positioning using a ruler. This results in processing efficiency five times that of a standard 3-in-1 busbar machine. Another surprise is that the machine supports program memory storage, meaning the operator only needs to enter parameters once and can simply call up the stored program in the future.

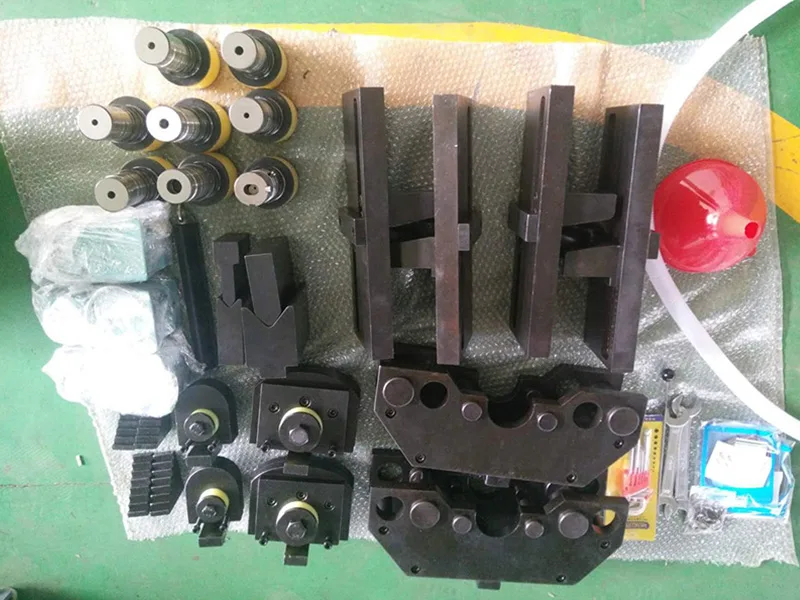

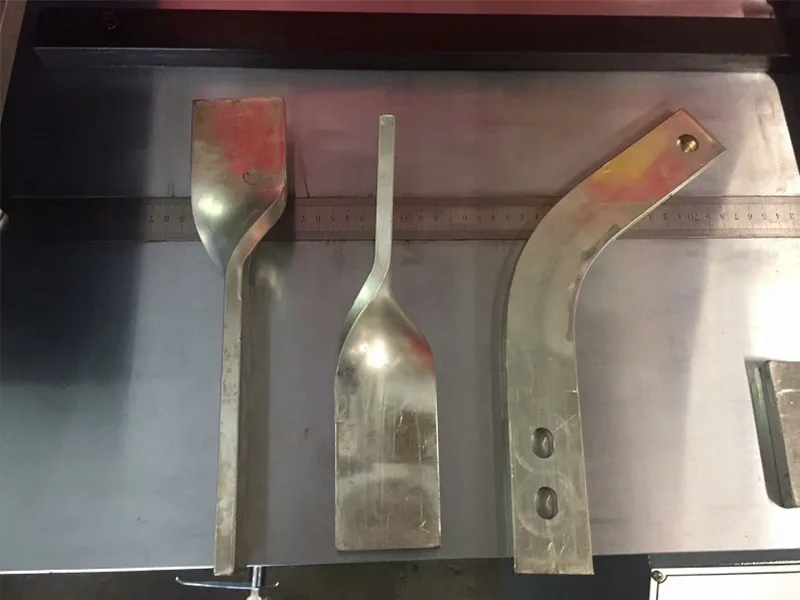

Mold list

Each of our busbar machines is standardly equipped with 5 sets bending molds, 8 sets punching molds and 1 set cutting mold. Our molds are made of Cr12Mov high-strength alloy steel, which has excellent wear resistance and strength, making the cross-section of busbar punching and cutting smooth and burr-free, and the service life is up to 30,000 times.

| Mold | Specification | Qty |

|---|---|---|

| Round Punching Mold | Ø7, Ø9, Ø11, Ø13, Ø17 | 5sets |

| Oval Punching Mold | Ø11×15, Ø13×18, Ø17×21 | 3sets |

| Vertical Bending Mold | R3, R5, R10, U-SHAPE | 4sets |

| Horizontal Bending Mold | R80 or R50 | 1set |

| Embossing Mold | / | 1set |

| Cutting Mold | / | 1set |

Note:The above molds are standard equipment and are free of charge. If your busbar bending requirements are unique, or if you require a punching mold with special specifications and shapes, please contact our technical engineer: Ms.Lisa and we can provide you with a one-on-one customized solution.

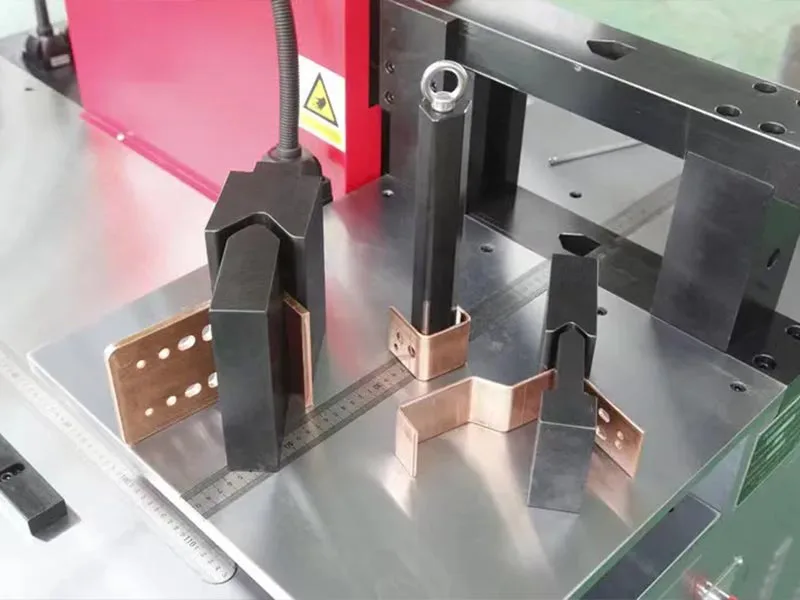

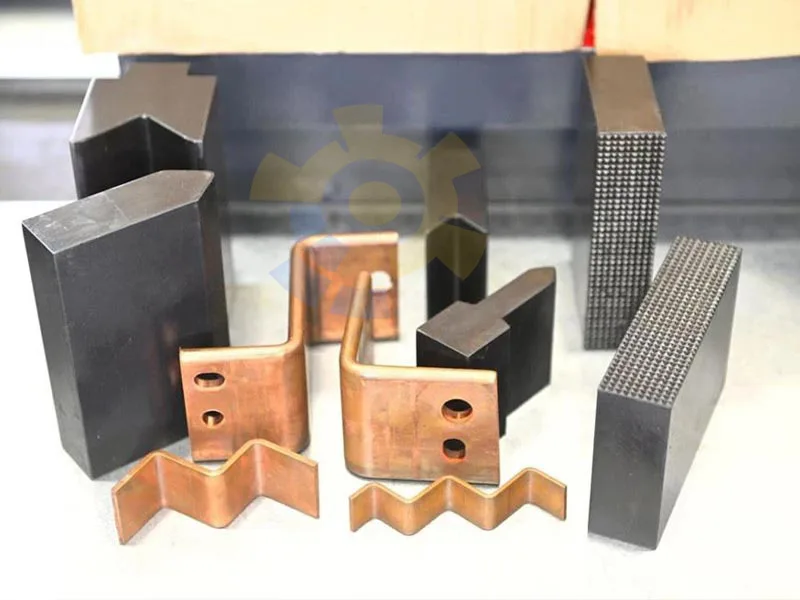

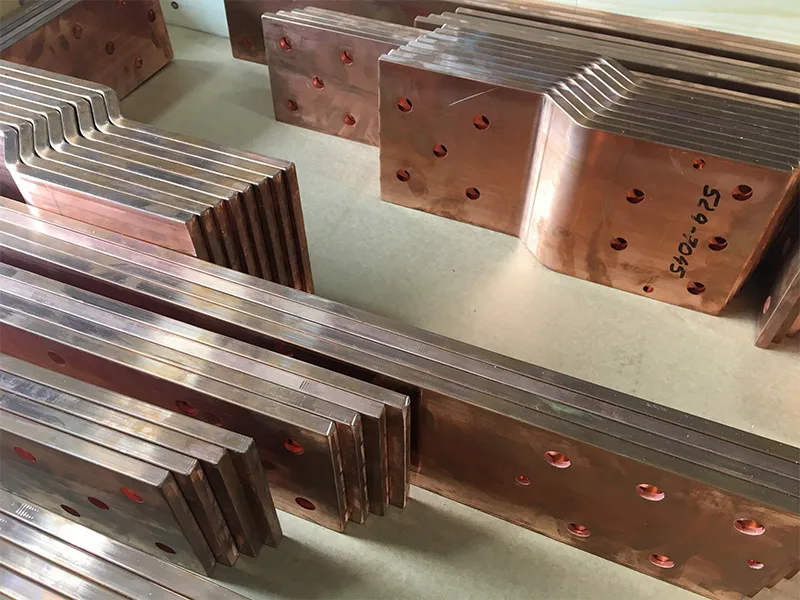

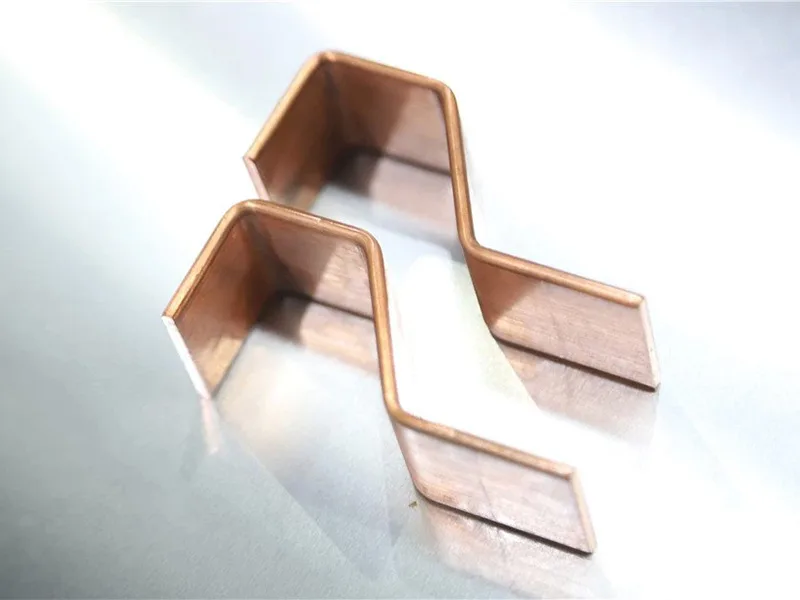

Busbar sample image gallery

SUNSHINE™ technical team has been insisting on iterating busbar processing technology to achieve a perfect match between software and hardware, so that every busbar processed by each device meets the design standards, busbar cross-section is smooth and burr-free, and ensures that copper busbar material waste is minimized and meets strict industry requirements.

- Bending Mold: Vertical bending (R3, R5, R10), horizontal bending (R80/R50), U-bend, embossing, twisting

- Punching Mold: Round, oval, square, rectangle, chamfer, special shape

- Cutting Mold

Contact us with questions?

WhatsApp us +86-15562468863 for technical support or customization.

About us

To date, electrical equipment manufacturers from 75 countries and regions worldwide (including the United States, Canada, Mexico, Brazil, Egypt, Turkey, Italy, Greece, Vietnam, Thailand, the Philippines, and Indonesia) have chosen SUNSHINE™ and MAC™ for their precise, stable, efficient, and reliable busbar punching, cutting, and bending solutions. With its superior mechanical manufacturing capabilities, SUNSHINE™ busbar machine are synonymous with economical and multi-function, while MAC™, with its sophisticated CNC technology and software, is synonymous with automation, efficiency, and precision.

SUNSHINE™

With over 2,540 satisfied customers and participation in over 58 international events, we remain committed to providing world-class busbar fabrication equipment and responsive technical support anytime, anywhere.

Our Services