Home | Busbar Machine | 3 in 1 Busbar Machine Pro | SS-30-3CNC PRO Busbar Fabrication Equipment

SS-30-3CNC PRO Busbar Fabrication Equipment

function

Basic parameters

description

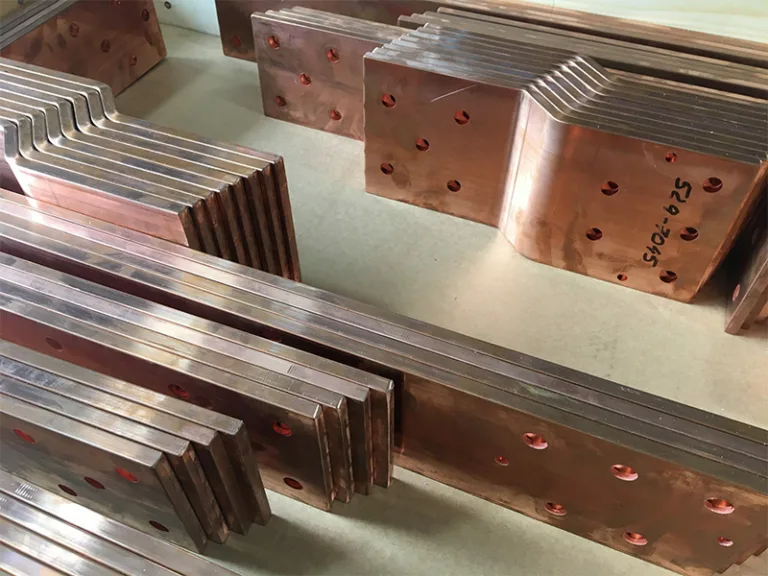

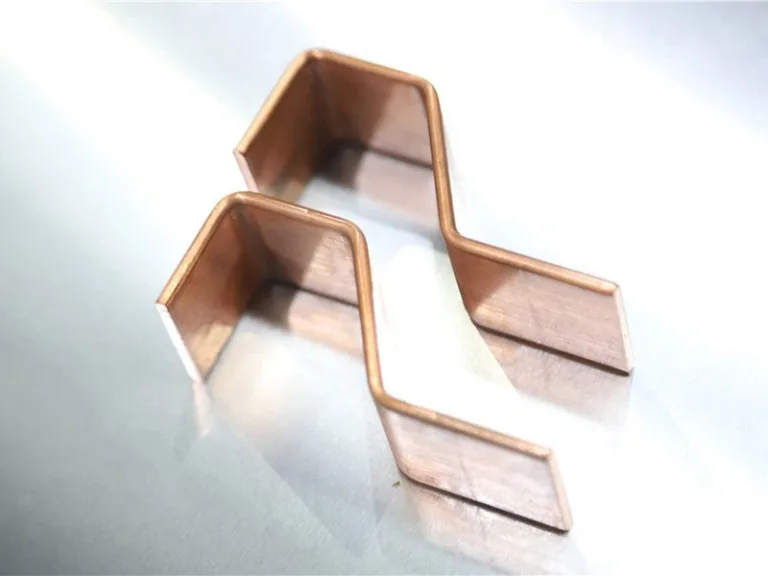

The SS-30-3CNC PRO busbar fabrication equipment is a highly efficient busbar processing machine suitable for a variety of simple and repeatable applications. It utilizes three independent 4kW motors, each providing hydraulic power for the punching, cutting, and bending units. It can process copper busbars up to 12mm thick and 160mm width, making it an economical choice for small and medium-sized electrical switchgear manufacturers.

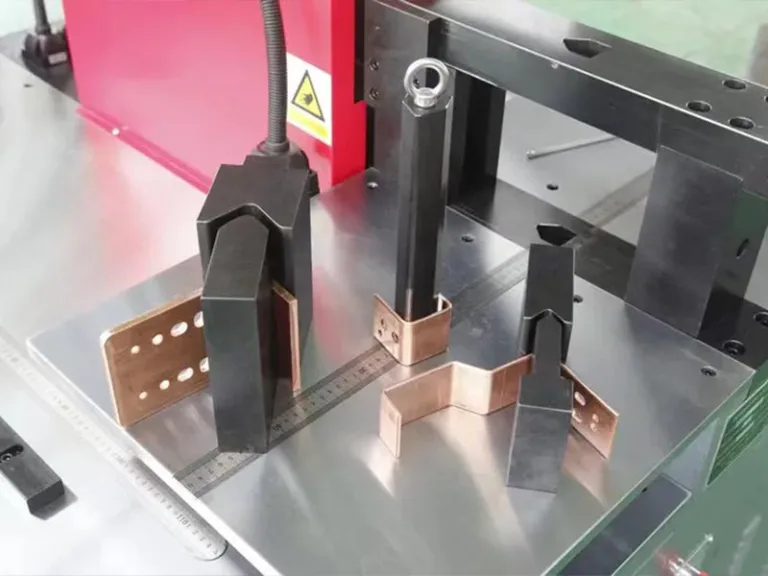

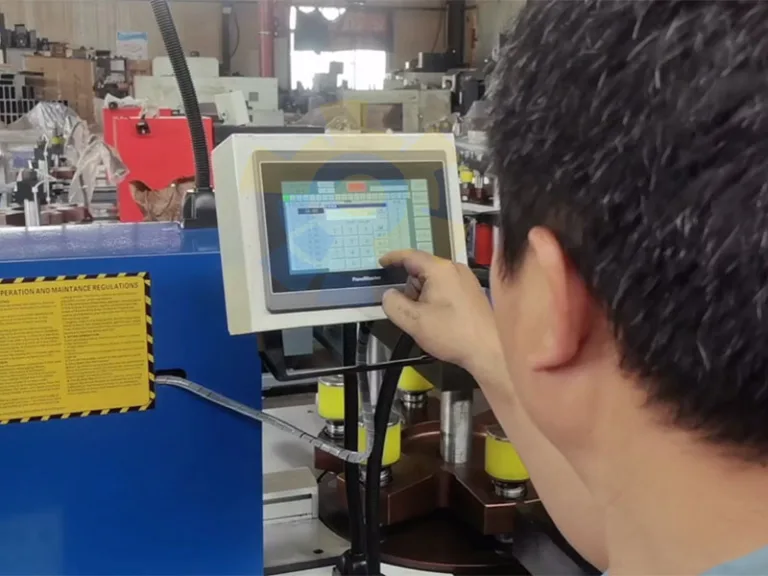

The automation level of SS-30-3CNC PRO busbar machine is better than that of SS-30-3CNC busbar machine. Unlike standard 3-in-1 busbar machines, the SS-30-3CNC PRO is equipped with four servo motors and four servo servers. A PLC precisely controls the movement of high-precision roller screws, enabling automated positioning of busbar punching, cutting, and bending positions. This eliminates the need for operators to measure busbar processing coordinates with a ruler, significantly improving busbar processing efficiency.

The SS-30-3CNC PRO busbar machine supports memory storage, capable of storing up to 100 drawing parameters. Operators no longer need to repeatedly enter processing parameters, significantly improving efficiency and reducing operational errors.

Product Video

parameters

| Model | SS-30-3CNC PRO |

| Max. Thickness | 12mm |

| Max. Width | 160mm |

| Pressure | 300KN |

| Punching Station | 6 |

| Punching Range | Φ4.3-Φ30 |

| Punching Error | ±0.1.5mm/m |

| Punching Length Stroke Limit | 1000mm |

| Punching Width Stroke Limit | 150mm |

| Bending Error | ±0.3º |

| Bending Length Stroke Limit | 1000mm |

| Cutting Length Stroke Limit | 1000mm |

| Motor Power | 4KW*3 |

| Servo Motor Power | 400W*4 |

| Voltage | 380V 50HZ(default) |

| PLC | Siemens for Bending+Punching+Cutting |

| HIM Mobile Panel | 3sets |

| Language | Chinese/English |

Mold List

| Round Punching Mold | Ø7, Ø9, Ø11, Ø13, Ø17 | 5sets |

| Oval Punching Mold | Ø11×15, Ø13×18, Ø17×21 | 3sets |

| Vertical Bending Mold | R3, R5, R10 | 3sets |

| U-SHAPE Mold | / | 1set |

| Horizontal Bending Mmold | R80 or R50 | 1set |

| Embossing Mold | 160mm | 1set |

| Cutting Mold | / | 1set |

Note: The molds mentioned above are standard configurations. If you need molds with different specifications or for special busbar shapes, our technical team can customize them free of charge. To contact our technical engineer, please email lisa@busbarmac.com.

images Gallery

*This information will not be shared with any dealers or individuals. Our collection and use of your personal information.