Home | Busbar Machine | CNC Busbar Bending Machine | NC.40ZB-1200 CNC busbar bending machine

NC.40ZB-1200 CNC busbar bending machine

function

Basic parameters

description

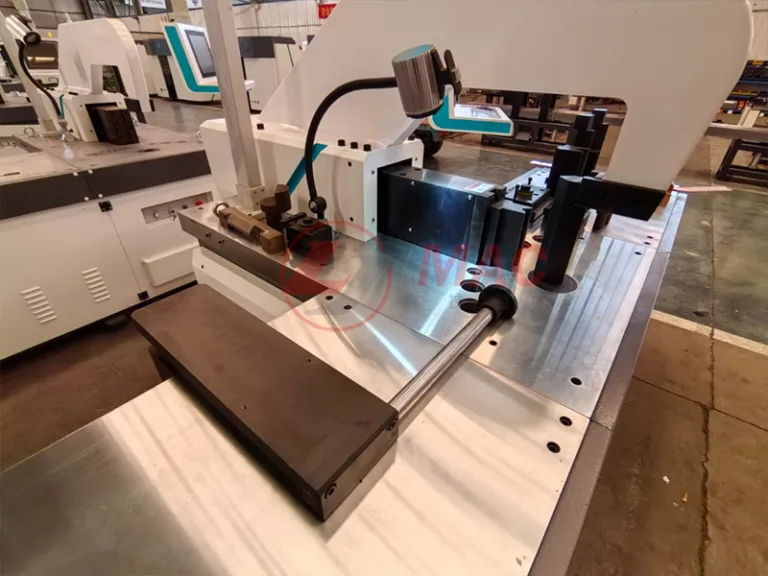

The NC.40ZB-1200 CNC busbar bender uses a 7.5kW servo motor to provide the bending force, offering superior bending angle accuracy and force compared to hydraulically driven systems.

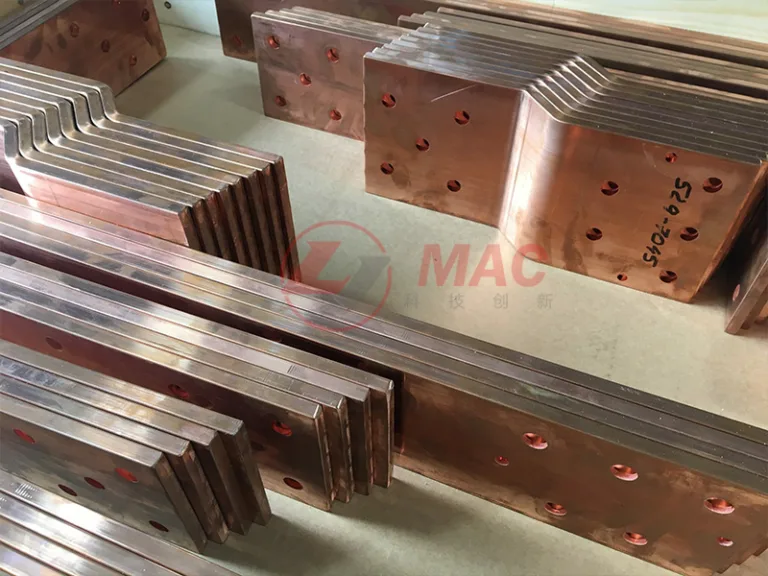

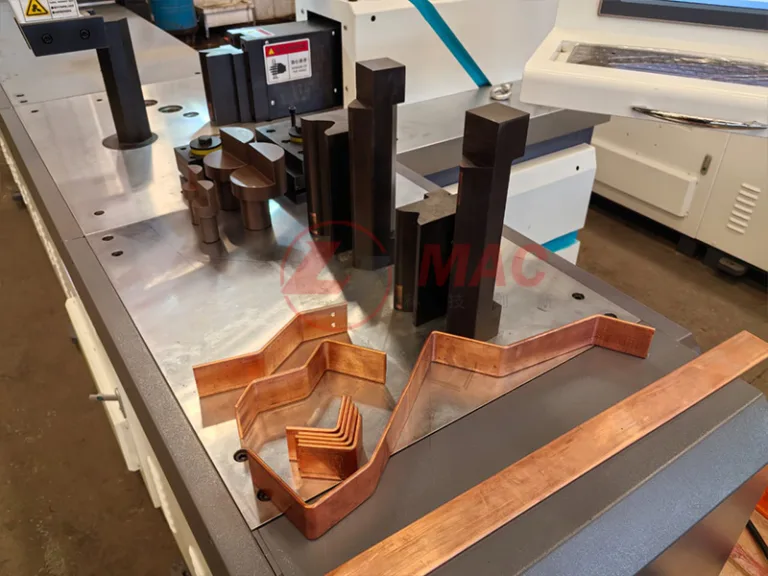

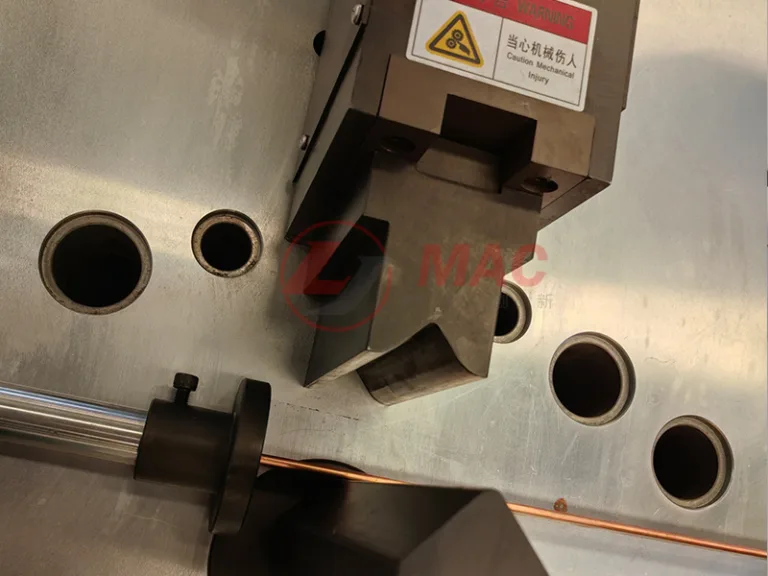

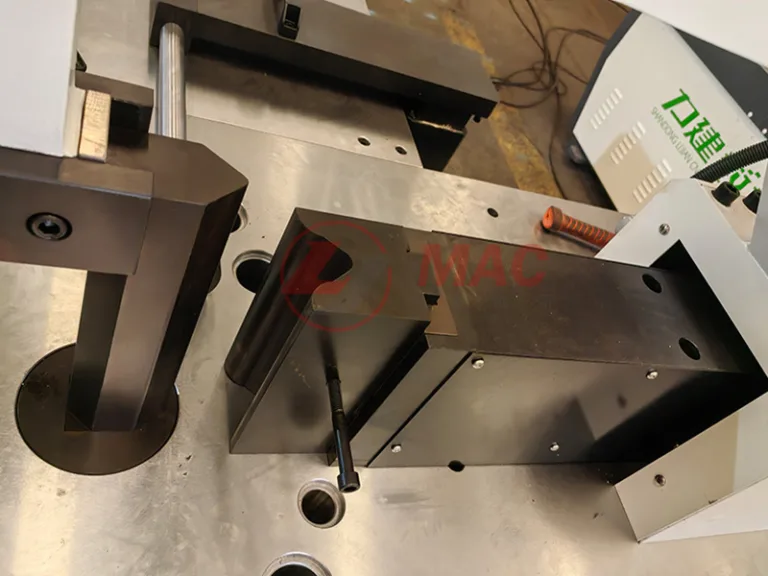

This busbar bender features horizontal bending, vertical bending, and twisting capabilities, and can process copper busbars up to 15mm thickness and 160mm width. Horizontal bending can process busbars up to 12mm x 120mm in size.

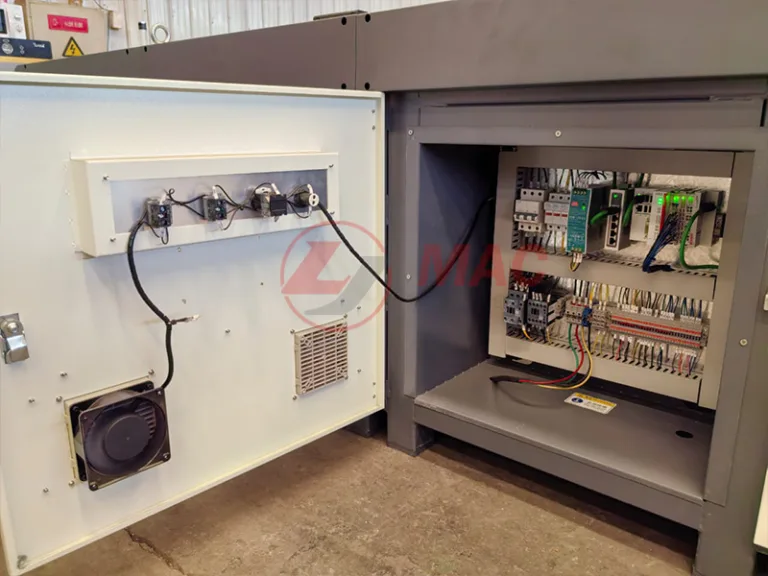

The NC.40ZB-1200 is programmed and operated via a modern, easy-to-use, 2-axis control touchscreen. Bending angles can be programmed and adjusted after the initial bend. The stroke setting can be adjusted in the program at any time in +/- 0.1° increments to offset material-related variances. The machine can share data with CNC busbar punching and cutting machine via Wi-Fi, creating an automated busbar punching, cutting, and bending production line.

The NC.40ZB-1200 busbar bender’s slow, automatic, and straightening modes can all be operated via a foot switch or manual control line. Optional automatic measurement and rebend functions ensure perfect bends regardless of material properties. For each bend, the NC.40ZB-1200 copper busbar bender performs an initial bend, measures, and then rebends each busbar, ensuring maximum process reliability and precision. The control system individually calculates the required stroke and springback compensation for optimal accuracy.

Product Video

parameters

| Model | NC.40ZB-1200 |

| Vertical Bending Max.Size | 15mm x 160mm |

| Horizontal Bending Max.Size | 12mm x 120mm |

| Pressure | 400KN |

| Spindle Stroke | 200mm |

| X-axis Servo Motor Power | 750W |

| X-axis Stroke Speed | 15m/min |

| Y-axis Servo Motor Power | 7.5KW |

| Y-axis Stroke Speed | Fastest 5m/min; Low: 1.25m/min |

| Bending Error | ±0.3° |

| Stopper Error | ±0.15mm |

| Stopper Length | 1200mm |

| Voltage | 380V 50HZ/60HZ(default) |

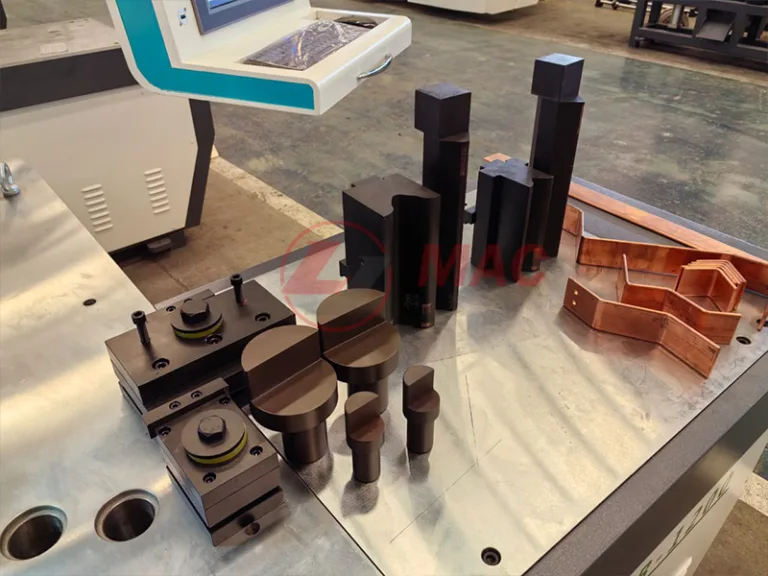

Mold List

| Vertical bending mold | R5, R10 | 2sets |

| Horizontal bending mold | R30, R100 | 2sets |

Note: The molds mentioned above are standard configurations. If you need molds with different specifications or for special busbar shapes, our technical team can customize them free of charge. To contact our technical engineer, please email lisa@busbarmac.com.

images Gallery

*This information will not be shared with any dealers or individuals. Our collection and use of your personal information.