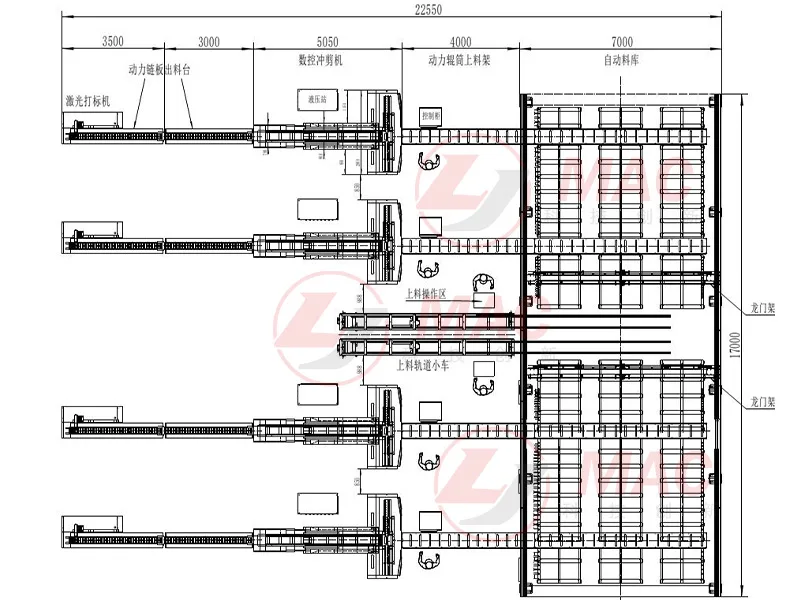

Automatic busbar production line

MAC™ automation system, consisting of a gantry system and automatic loading and unloading system, combines with our MX602K series CNC busbar punching and shearing machine to create an automated busbar production line, marking a significant step towards automated solutions for busbar manufacturing equipment. MAC™’s proven automation technology will maximize efficiency in your busbar processing workshop, reducing labor costs.

Whether you are looking for a fully automatic busbar processing solution or a semi-automatic busbar processing solution, our technical team can provide you with a customized busbar production line solution to help increase your busbar production capacity.

Gantry system

Automatic loading and unloading system

MAC™ Gantry System is a storage system that replaces electric gantry suction cup machines. The storage and movement of copper busbars is fully automated by the gantry system, providing operators with the option of storing busbars of varying sizes simultaneously. MAC™ automatic unloading and loading system automatically feeds the copper busbars into our busbar punching and shearing machines. Material of varying widths or thicknesses can be processed sequentially without manual intervention, optimizing the busbar processing process.

Optional

- MX602K Series CNC Busbar Punching and Shearing Machine

- Parts Marking: Laser Marking/Dot Marking

- CNC Busbar Chamfering Machine

- Automatic Sorting Device

- Safety Light Grating

- MES System Integration

- ERP System Integration and Development

Contact us with questions?

WhatsApp us +86-15562468863 for technical support or customization.

How it works

Using MAC™ nesting software, operators import busbar drawings, generate part processing codes, and send them to the production line management system for intelligent scheduling optimization. The operator then selects the corresponding busbar processing line in the management system and issues batch production instructions. The gantry system automatically picks up busbars of different specifications, moves them, and places them on the corresponding busbar processing line’s automatic conveyor belt.

A conveyor belt automatically transports the copper busbars to the busbar punching and shearing area. The busbar punching and shearing machine program detects the busbars, reads the punching and shearing code issued by the production line management system, and then performs the punching and shearing process. Finally, a sorting device categorizes the finished busbar parts according to their specifications.

Note: Thanks to MAC™ nesting software and its quick configuration feature, MX602K series CNC busbar punching and cutting machine, NC.40ZB series CNC busbar bending machine, and CNC busbar chamfering machine can share data via Internet Protocol. Together with the automatic loading and unloading system, they form a CNC busbar production line. Please contact our technical engineer Ms.Lisa for customized busbar production line solutions.

About us

To date, electrical equipment manufacturers from 75 countries and regions worldwide (including the United States, Canada, Mexico, Brazil, Egypt, Turkey, Italy, Greece, Vietnam, Thailand, the Philippines, and Indonesia) have chosen SUNSHINE™ and MAC™ for their precise, stable, efficient, and reliable busbar punching, cutting, and bending solutions. With its superior mechanical manufacturing capabilities, SUNSHINE™ busbar machine are synonymous with economical and multi-function, while MAC™, with its sophisticated CNC technology and software, is synonymous with automation, efficiency, and precision.

SUNSHINE™

With over 2,540 satisfied customers and participation in over 58 international events, we remain committed to providing world-class busbar fabrication equipment and responsive technical support anytime, anywhere.

Our Services