CNC busbar bending machine: servo drive, automatic, high precision, 60% energy saving

To efficiently bend copper and aluminum busbars, MAC™ integrates the busbar processing advantages of two busbar bending machine manufacturers: SUNSHINE™’s advanced machinery manufacturing and MAC™’s nested software technology. Based on nearly 20 years of best practices in the development of CNC bending machine, the functions of each busbar bending machine are derived from real customers and their actual factory needs.

MAC™ busbar bending machine are highly regarded by our 1,250 customers for their precision and reliability. Whether you’re bending copper or aluminum busbar, our proprietary bending technology meets today’s demands for consistent and efficient bending. Sold in 75 countries and regions, MAC™ CNC busbar bending machine are the preferred choice for switchgear manufacturers and panel manufacturers worldwide.

NC.40ZB-2000 busbar bending machine

$ Request Price

NC.40ZB-1200 CNC busbar bending machine

$ Request Price

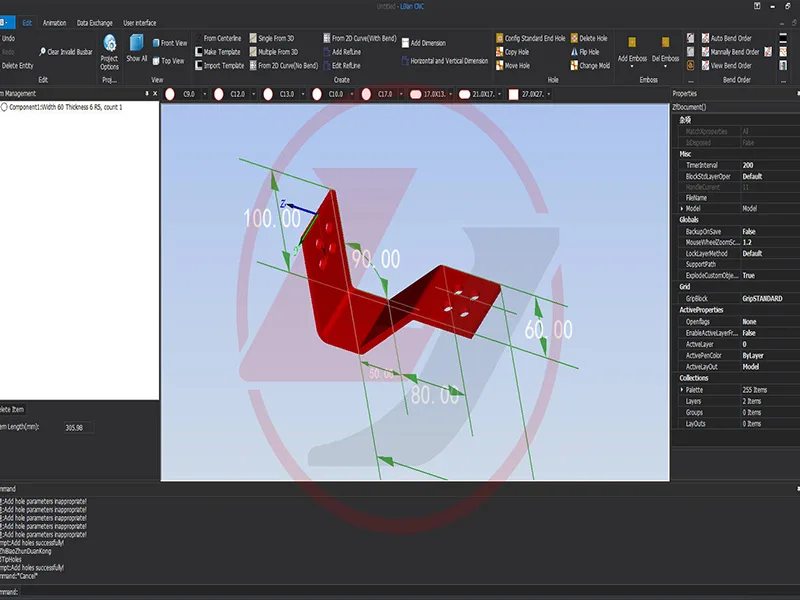

MAC™ CNC busbar bending machine utilize an electric servo drive system, which is 60% more energy-efficient than hydraulic systems and offers higher precision. They are designed specifically for high-load, high-precision bending. Our unique MAC™ bending mold and springback compensation technology ensure bend angle accuracy within 0.3°, delivering unparalleled consistency across vertical, horizontal, and twist bends.

Contact us with questions?

WhatsApp us +86-15562468863 for technical support or customization.

NC40.ZB series Busbar Bending Machine

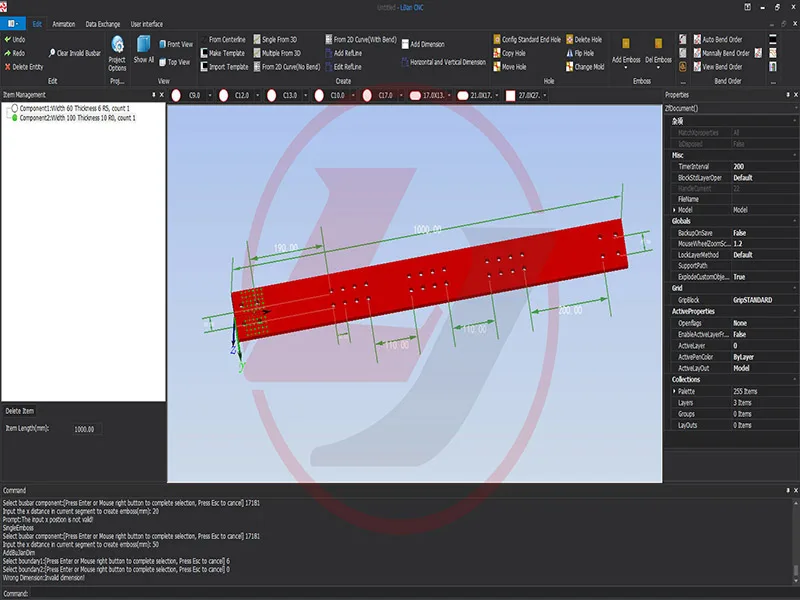

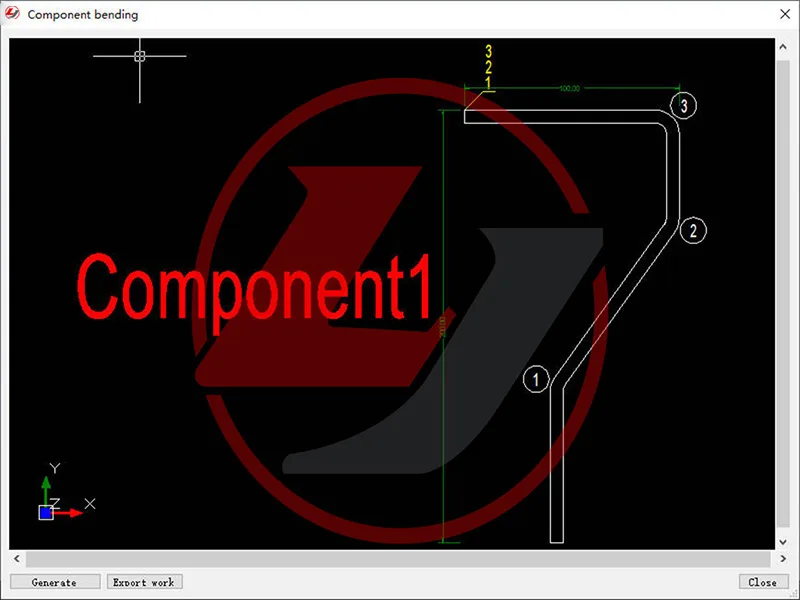

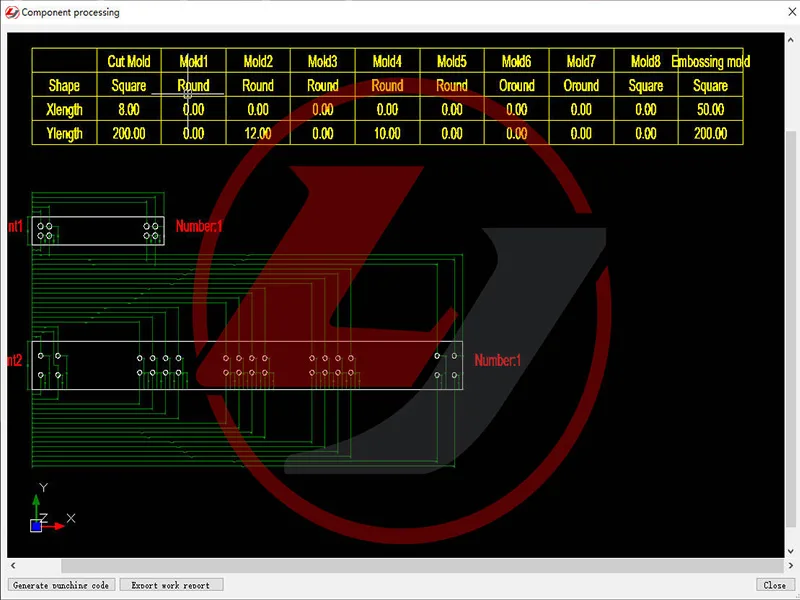

NC.40ZB series CNC busbar bending machine also feature optional automatic measurement and secondary bending functions, ensuring perfect bends regardless of material properties. Automatic measurement tools and associated software calculate springback data based on bend tables stored in the control system, which can be added to or edited as needed.

For each bend, the NC.40ZB series copper busbar bending machine performs an initial bend, measures, and then performs a secondary bend on each copper busbar, ensuring maximum process reliability and precision. The control system individually calculates the required stroke and springback compensation for optimal accuracy. The pre-bend length and stop position are also automatically calculated.

Note: Leveraging MAC™ nesting software and quick configuration capabilities, our NC.40ZB series CNC busbar bending machine can share data with the MX602K series CNC busbar punching and cutting machine and cnc busbar chamfering machine. Together with the automatic loading and unloading system, they form a CNC busbar production line. Contact our technical engineer Ms.Lisa for a customized busbar production line solution.

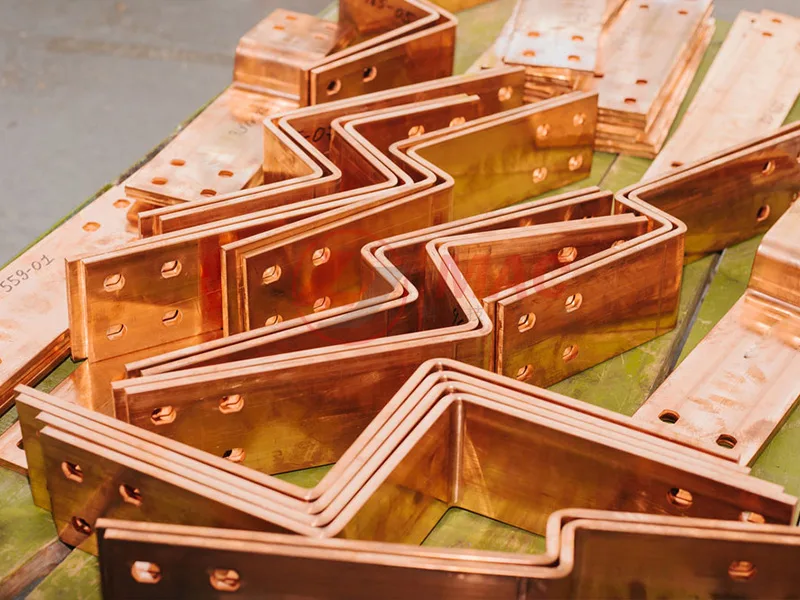

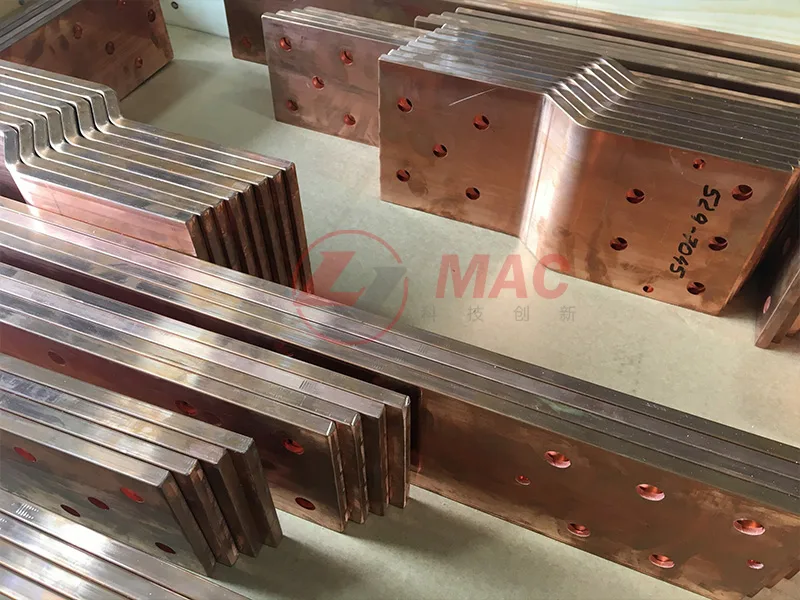

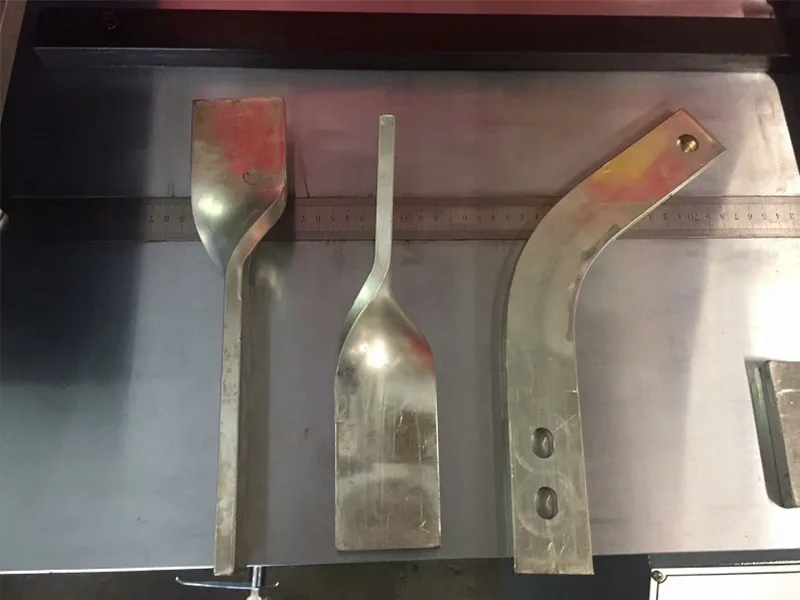

Busbar sample image gallery

Our technical team has been insisting on iterating busbar processing technology to achieve a perfect match between software and hardware, so that every busbar processed by each device meets the design standards, and ensures that copper busbar material waste is minimized and meets strict industry requirements.

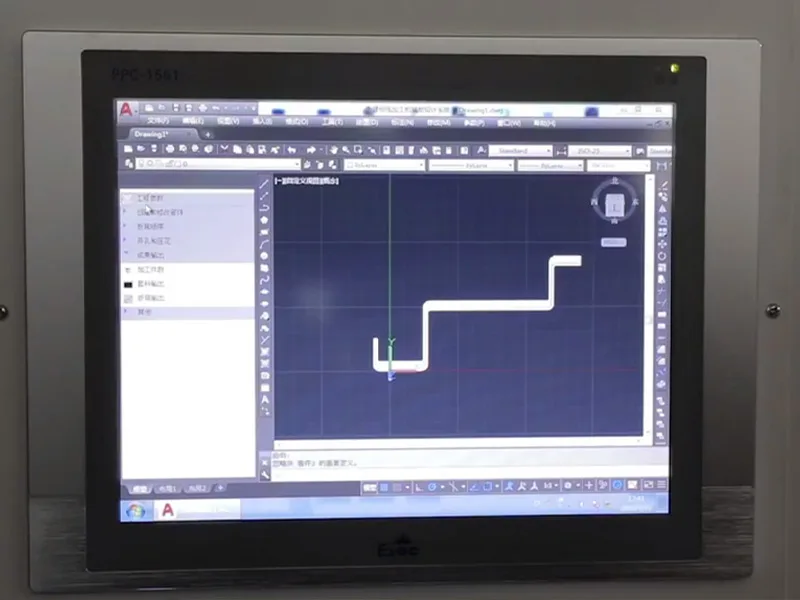

MAC nesting software

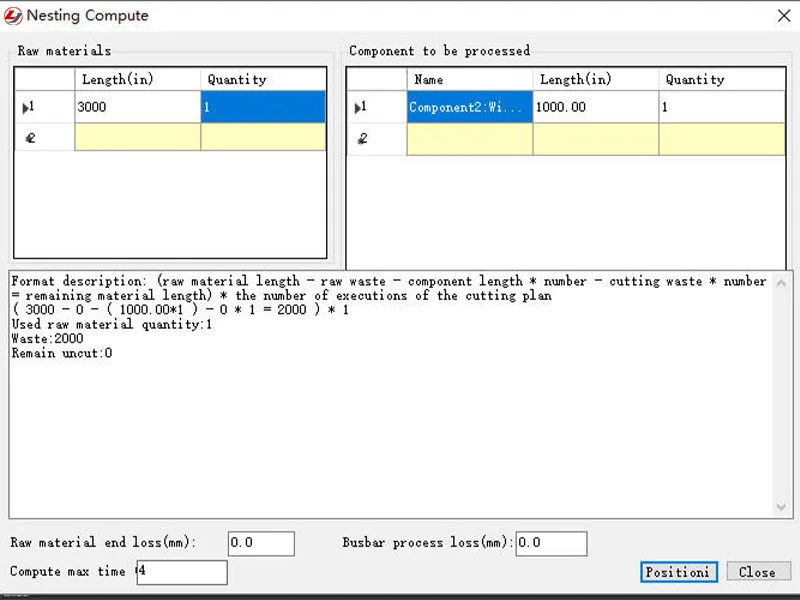

In 2005, MAC™ Software’s technical engineering team launched version 1.0 of its Nesting software. After nearly 20 years of best practices in customer factories and countless upgrades and iterations, MAC™ Nesting software seamlessly integrates CAD/CAM data and can handle a wide range of complex customer drawings and production processes. Its intelligent residual material management system automatically optimizes part processing paths, increasing copper busbar utilization to over 98% and effectively reducing scrap rates.

- Supported formats: 2D (.dxf, .dwg), 3D (.stp, .step)

- 2D/3D drawing import, creation, and editing

- Nesting calculation

- Drawing conversion to production code (html, CSV)

Automatic unloading and loading system

MAC™ has launched an automatic unloading and loading system for its MX602K series CNC busbar punching machines. This system, integrated into the MES system, supports intelligent batch order scheduling and automatically schedules production based on order priority. This system automates copper busbar processing, reduces manual labor, and increases production line utilization by over 20%, significantly improving busbar production efficiency.

This new programmable clamping and loading system streamlines automated production processes without requiring additional personnel. Operators can load copper bar stock of various widths and lengths according to a work list. Once programmed, the system picks a copper bar from a sorted shelf, assesses its dimensions, clamps it in place, performs the specified punching and cutting operations, and then delivers it to the finished product area.

The automatic unloading and loading system consists of a sorting and unpacking area, a manual stacking area, a storage area, and a loading area. It also has a reserved bending processing area (CNC busbar bending machine), a laser marking area, and a chamfering processing area (CNC busbar chamfering machine). The overall layout is square and reasonable, and it occupies a small area.

About us

To date, electrical equipment manufacturers from 75 countries and regions worldwide (including the United States, Canada, Mexico, Brazil, Egypt, Turkey, Italy, Greece, Vietnam, Thailand, the Philippines, and Indonesia) have chosen SUNSHINE™ and MAC™ for their precise, stable, efficient, and reliable busbar punching, cutting, and bending solutions. With its superior mechanical manufacturing capabilities, SUNSHINE™ busbar machine are synonymous with economical and multi-function, while MAC™, with its sophisticated CNC technology and software, is synonymous with automation, efficiency, and precision.

SUNSHINE™

With over 2,540 satisfied customers and participation in over 58 international events, we remain committed to providing world-class busbar fabrication equipment and responsive technical support anytime, anywhere.

Our Services