Necessity of Busbar Chamfering

According to the consensus and mandatory regulations in the global electrical safety field, any qualified low-voltage switchgear and control equipment that needs to be put on the market, as long as its manufacturing and sales comply with the IEC 61439 or EN 61439 series of standards, its copper busbar must be chamfered to prevent tip discharge, eliminate burrs and sharp edges to ensure personal safety and equipment insulation performance. This is the basic prerequisite for ensuring equipment safety and obtaining market access permits.

CNC Busbar Chamfering Machine

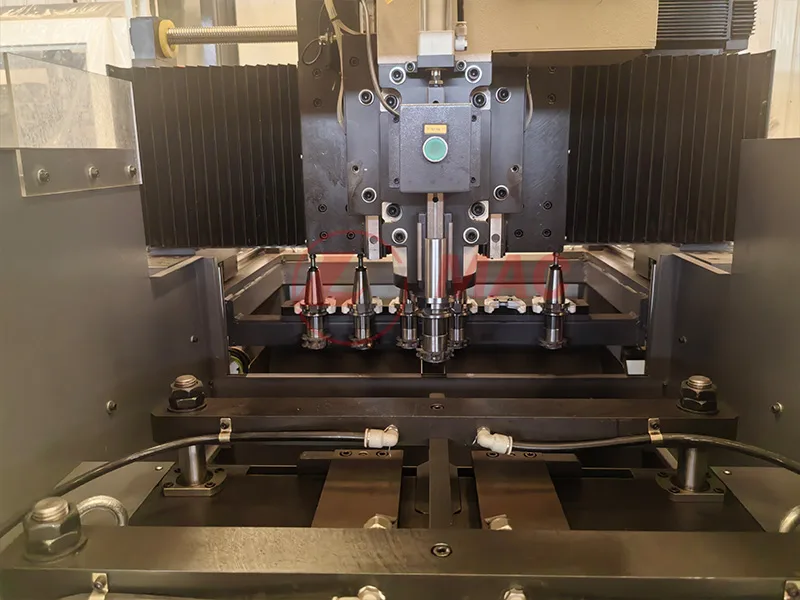

MAC™ CNC busbar chamfering machine offer proven milling technology for preventing discharges at busbar tips and removing sharp edges. Whether milling copper busbar corners or machining segmented arcs, our proprietary milling technology meets the essential safety requirements for electric shock protection and dielectric properties for low-voltage switchgear as specified in the IEC 61439 standard.

MAC™ CNC busbar chamfering machine features a five-axis design, a max spindle speed of 6000 rpm, and a positioning ±0.05mm accuracy . It can process copper busbars with thicknesses ranging from 4 to 16mm, widths from 30 to 200mm, and lengths from 150 to 6000mm. The machine is also equipped with an automatic milling fluid spray system, ensuring high milling finish. The machine intelligently controls the feed speed in sections based on the amount of cutting required at each workpiece location, and the metal cutting fluid is automatically filtered and recycled.

- 5-axis control, using a German Beckhoff PLC.

- BT40 toolholders, in-line tool magazine, automatic tool change, and high precision.

- Automatic milling fluid spray system with automatic filtration and recycling.

- Auto-centering technology and a pressurizing device ensure workpiece stability.

- Embedded automatic graphical programming software.

Note: Leveraging MAC™ nesting software and quick configuration capabilities, our cnc busbar chamfering machine can share data with MX602K series CNC busbar punching and cutting machine and NC.40ZB series CNC busbar bending machine. Together with the automatic loading and unloading system, they form a CNC busbar production line. Contact our technical engineer Ms.Lisa for a customized busbar production line solution.

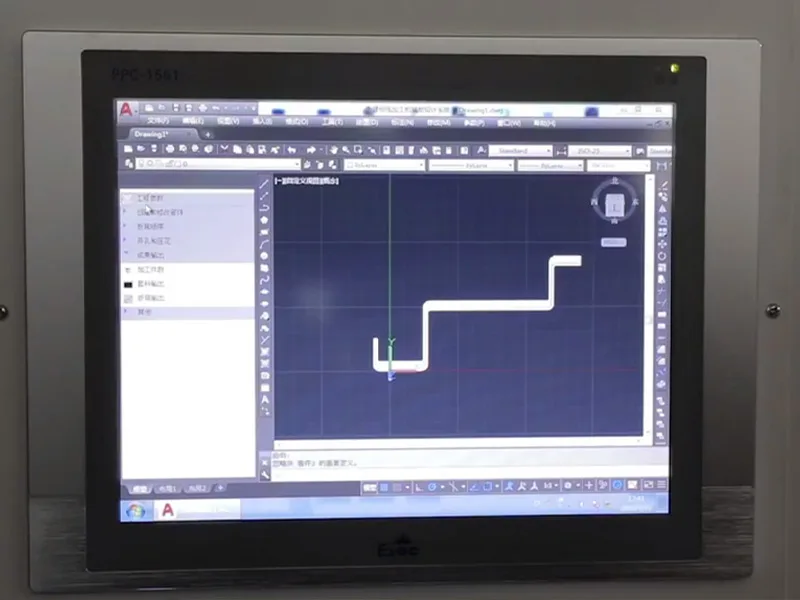

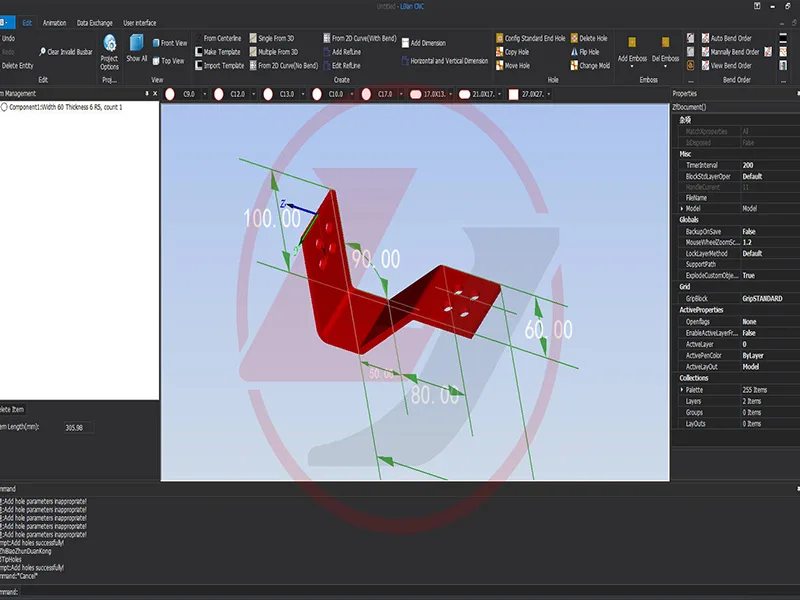

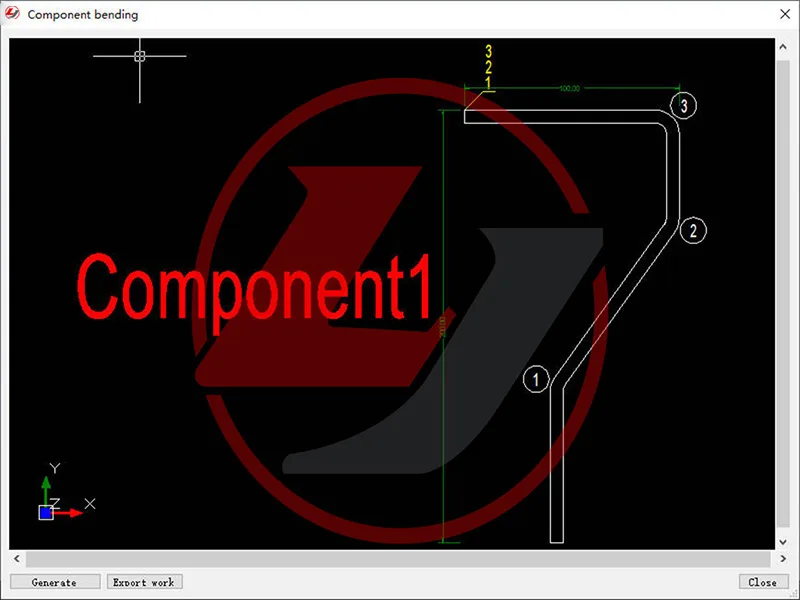

MAC™ busbar chamfering machine utilizes embedded automatic graphical programming software independently developed by MAC™ technical team, enabling automated programming. Operators do not need to understand various codes or master traditional machining center operations. Simply refer to the graphics and enter a few parameters, and the machine automatically generates the machine code. This saves time compared to manual programming and eliminates potential coding errors.

Technical Parameters

| CNC axes | 5-axes |

| Busbar Length | 150-6000mm |

| Busbar Thickness | 4-16mm |

| Busbar width | 30-200mm |

| Max spindle speed | 6000r/min |

| Spindle servo motor power | 3.7KW |

| Max X-axis travel | 525mm |

| X-axis positioning error | ±0.08mm |

| Max Y-axis speed | 15m/min |

| X-axis servo motor power | 2KW |

| Max Y-axis travel | 500mm |

| Y-axis positioning error | ±0.08mm |

| Max Y-axis speed | 15m/min |

| Y-axis servo motor power | 2KW |

| Max Z-axis travel | 130mm |

| Z-axis positioning error | ±0.05mm |

| Z-axis servo motor power | 1KW |

| C-axis servo motor power | 0.75KW |

| Air pressure | 0.6-0.8MPa |

| Hydraulic pump motor power | 2.2KW |

milling cutter mold

| milling cutter | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm | 6sets |

Contact us with questions?

WhatsApp us +86-15562468863 for technical support or customization.

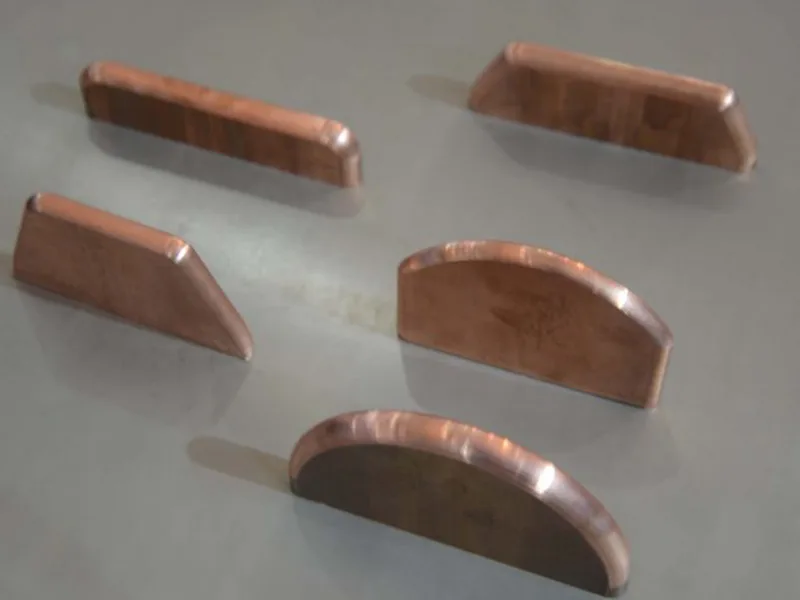

Busbar sample image gallery

Our technical team has been insisting on iterating busbar processing technology to achieve a perfect match between software and hardware, so that every busbar processed by each device meets the design standards, and ensures that copper busbar material waste is minimized and meets strict industry requirements.

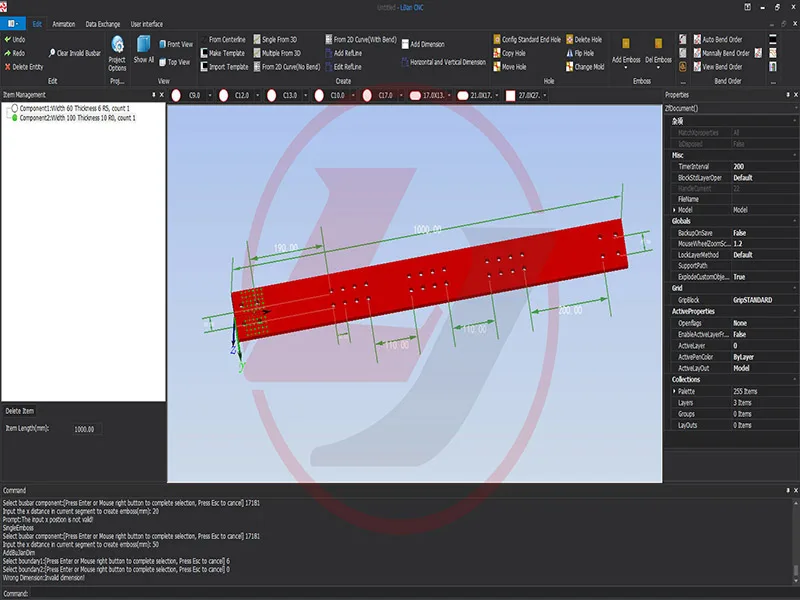

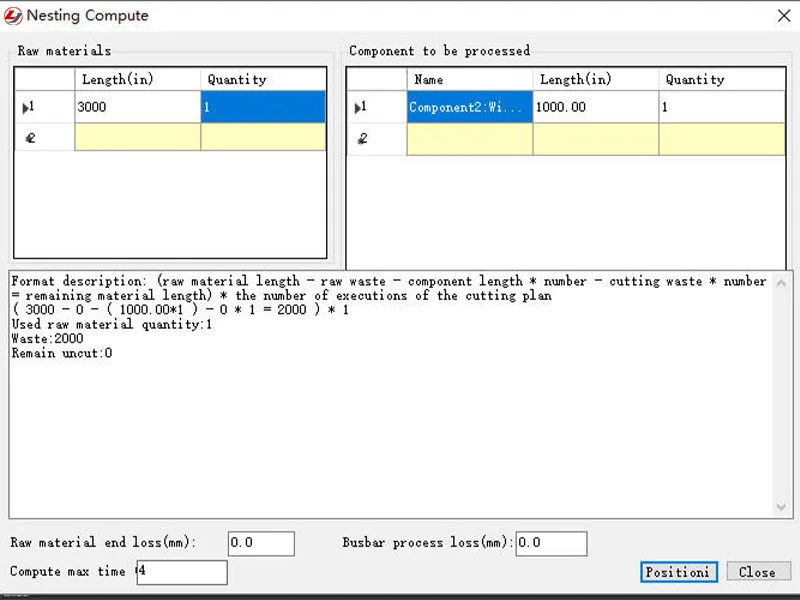

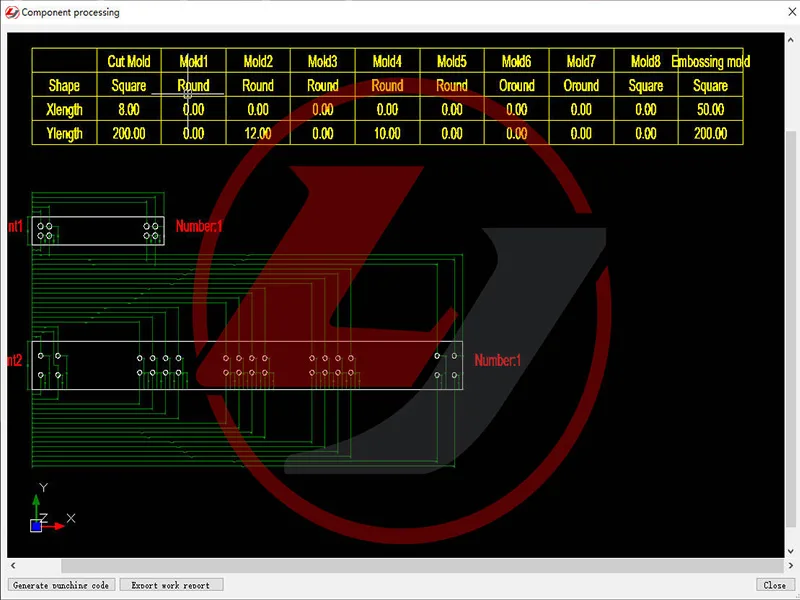

MAC nesting software

In 2005, MAC™ Software’s technical engineering team launched version 1.0 of its Nesting software. After nearly 20 years of best practices in customer factories and countless upgrades and iterations, MAC™ Nesting software seamlessly integrates CAD/CAM data and can handle a wide range of complex customer drawings and production processes. Its intelligent residual material management system automatically optimizes part processing paths, increasing copper busbar utilization to over 98% and effectively reducing scrap rates.

- Supported formats: 2D (.dxf, .dwg), 3D (.stp, .step)

- 2D/3D drawing import, creation, and editing

- Nesting calculation

- Drawing conversion to production code (html, CSV)

About us

To date, electrical equipment manufacturers from 75 countries and regions worldwide (including the United States, Canada, Mexico, Brazil, Egypt, Turkey, Italy, Greece, Vietnam, Thailand, the Philippines, and Indonesia) have chosen SUNSHINE™ and MAC™ for their precise, stable, efficient, and reliable busbar punching, cutting, and bending solutions. With its superior mechanical manufacturing capabilities, SUNSHINE™ busbar machine are synonymous with economical and multi-function, while MAC™, with its sophisticated CNC technology and software, is synonymous with automation, efficiency, and precision.

SUNSHINE™

With over 2,540 satisfied customers and participation in over 58 international events, we remain committed to providing world-class busbar fabrication equipment and responsive technical support anytime, anywhere.

Our Services