Busbar Punching, Cutting, and Bending Machine Manufacturer in China

SUNSHINE™ busbar machine are highly respected for their economy and quality, especially by small and medium-sized electrical panel manufacturers and high and low voltage switchgear factories around the world. Mahmoud Abou Elfetouh, technical engineer of ELC Energy For Industries in Egypt, said: “SUNSHINE™ is a very commendable Chinese busbar machine manufacturer brand. Its high quality, professional technical support and fast after-sales service are the key to our company’s continued cooperation with SUNSHINE for up to 5 years.”

For over 20 years, SUNSHINE™ technical team has positioned busbar fabrication machine as “economical, efficient, and multifunctional.” We have been committed to the technological evolution and manufacturing of busbar processing machine, including standard busbar punching, cutting, and bending machine, professional 3-in-1 busbar machine, and portable busbar machine. The mature busbar punching, cutting and bending technologies make SUNSHINE™ busbar fabrication equipment the preferred choice for global electrical panel manufacturers and switchgear manufacturers.

Contact us to learn more about our 3 in 1 busbar machine or to request best quote.

CNC busbar machine: fully automated, high precision and high efficiency.

With the maturity and accumulation of SUNSHINE™ busbar machine punching, cutting and bending technology, in 2010 our technical team embarked on the road of CNC automation research and development of busbar machines, and launched a new CNC busbar machine brand “MAC™“: Modernization, Automation, CNC. MAC™ CNC busbar machine is sought after by large-scale electrical panel manufacturers and high and low voltage switchgear manufacturers around the world for their full automation, high precision and high efficiency.

Whether you’re producing a single busbar component or hundreds of thousands, MAC™ technical team provides solutions with ultimate flexibility. Our advanced batch order intelligent scheduling system minimizes scrap and maximizes raw material utilization, increasing copper busbar raw material utilization to over 98%.

Contact us with questions?

WhatsApp us +86-15562468863 for technical support or customization.

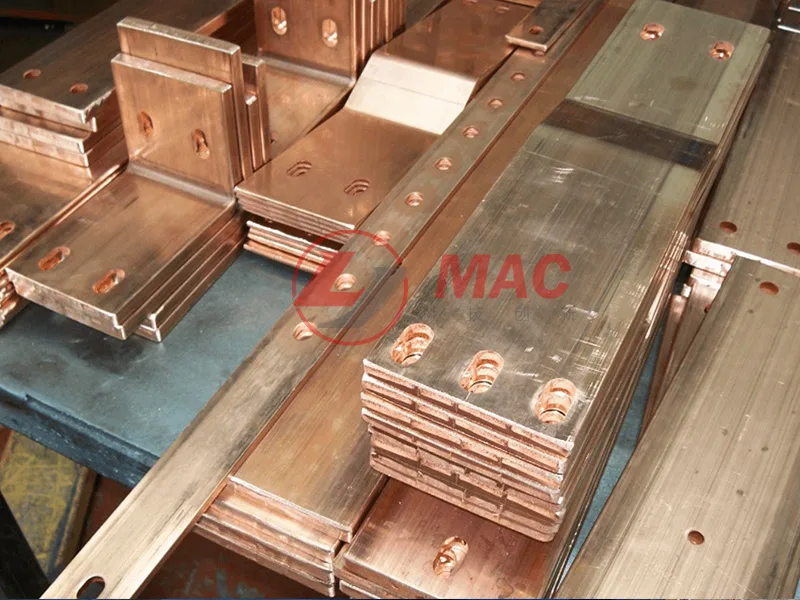

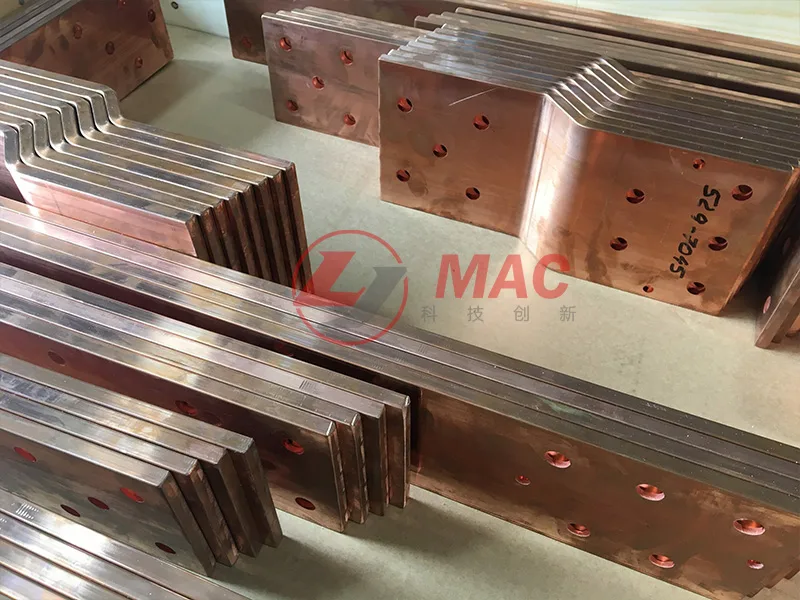

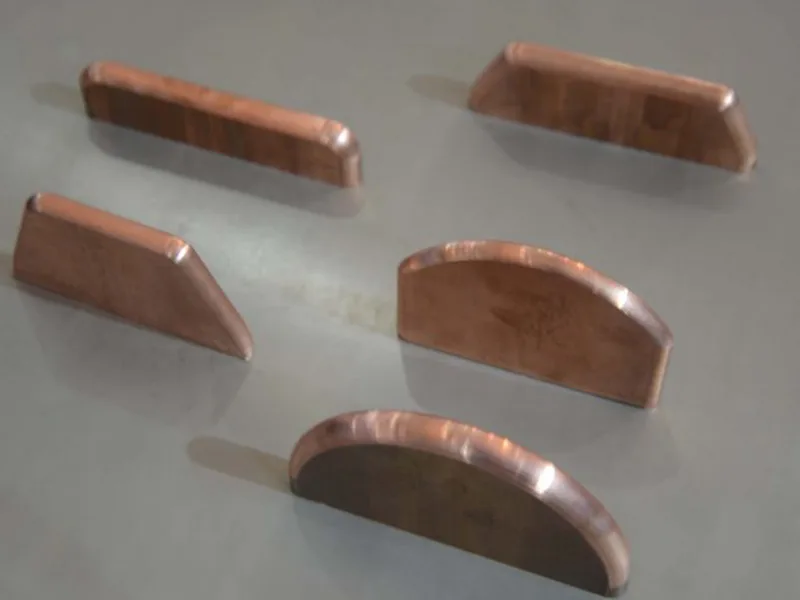

Busbar sample image gallery

SUNSHINE™ technical team has been insisting on iterating busbar processing technology to achieve a perfect match between software and hardware, so that every busbar processed by each device meets the design standards, busbar cross-section is smooth and burr-free, and ensures that copper busbar material waste is minimized and meets strict industry requirements.

About us

To date, electrical equipment manufacturers from 75 countries and regions worldwide (including the United States, Canada, Mexico, Brazil, Egypt, Turkey, Italy, Greece, Vietnam, Thailand, the Philippines, and Indonesia) have chosen SUNSHINE™ and MAC™ for their precise, stable, efficient, and reliable busbar punching, cutting, and bending solutions. With its superior mechanical manufacturing capabilities, SUNSHINE™ busbar machine are synonymous with economical and multi-function, while MAC™, with its sophisticated CNC technology and software, is synonymous with automation, efficiency, and precision.

SUNSHINE™

With over 2,540 satisfied customers and participation in over 58 international events, we remain committed to providing world-class busbar fabrication equipment and responsive technical support anytime, anywhere.

Our Services